Heathcoat are recognised as the leading global supplier of parachute fabrics for space, military and sports through our unique DecelAir® range.

The DecelAir® range includes ‘Superlight’, weighing 24gsm or less.

The DecelAir® range includes ‘Extreme’ for brake chutes.

Experience

Heathcoat Fabrics has almost 100 years of proven experience in manufacturing parachute fabrics. As market demands evolve, our dedicated development team leads the way in producing innovative solutions to meet the latest industry requirements.

We design and produce fabrics tailored to diverse parachute applications, offering a wide range of weights and finishes. This includes high-strength, lightweight fabrics for canopies and robust fabrics for parachute packs.

Parachute applications

Our woven and knitted fabrics are used in various parachute applications found in:

- Man-carrying parachutes – sport & military

- Cargo-carrying parachutes

- Recovery chutes – rockets, landers and other space craft, UAVs and drones

- Rescue chutes – paragliders

- Ejector seat canopies

- Harnesses/parachute packs [load bearing meshes and 3D spacetec® textiles]

- Drag chutes – rocket propelled cars & Jet propelled boats

Heathcoat DecelAir® & DecelAir® Superlight

– celebrating over 20 years of successful space landings

Versatile production

At Heathcoat, our comprehensive vertical manufacturing capabilities, from R&D, warping and weaving to coloration, finishing and in-house testing, gives us control over every stage of production and enables our customers to define fabric properties and specifications from the design stage. This unique flexibility makes Heathcoat DecelAir® fabrics the leading choice for military, sports, and space applications, such as NASA’s MARS2020 mission.

Features and benefits

DecelAir® fabrics offer many unique advantages including:

- Superior heat and UV resistance

- Canopy fabrics that are incredibly lightweight, strong and durable

- Tailored to individual requirements and dyed in-house

- Supply a wide range of military specification such as PIA and MIL-C

- Parachute packs being available with a rotproof finish

- ISO 9001 Quality Management certification

- ISO14001 Environmental Management certification

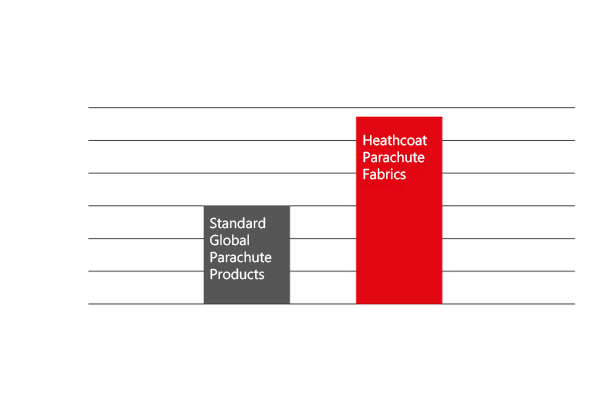

Breadth of capability

You will find Heathcoat parachute fabrics performing across the world – and beyond. It is our sheer diversity of applications that inspires us to redraw the parameters of performance. Heathcoat Advanced Yarns® used in our DecelAir® Superlight fabric are designed to withstand the most extreme and hostile conditions. Our DecelAir® Extreme range features ultra-durable materials such as Kevlar® and Twaron®. This engineering expertise has produced remarkable products including the lightest reserve chute fabric currently available for parachutists, drones and paragliding rescue.

Watch our DecelAir® Superlight fabric pass the toughest of tests

“…the material is quite remarkable – a really fantastic job in designing it.”

“…big congratulations are owed to you guys for working with us to engineer an impressive material.”