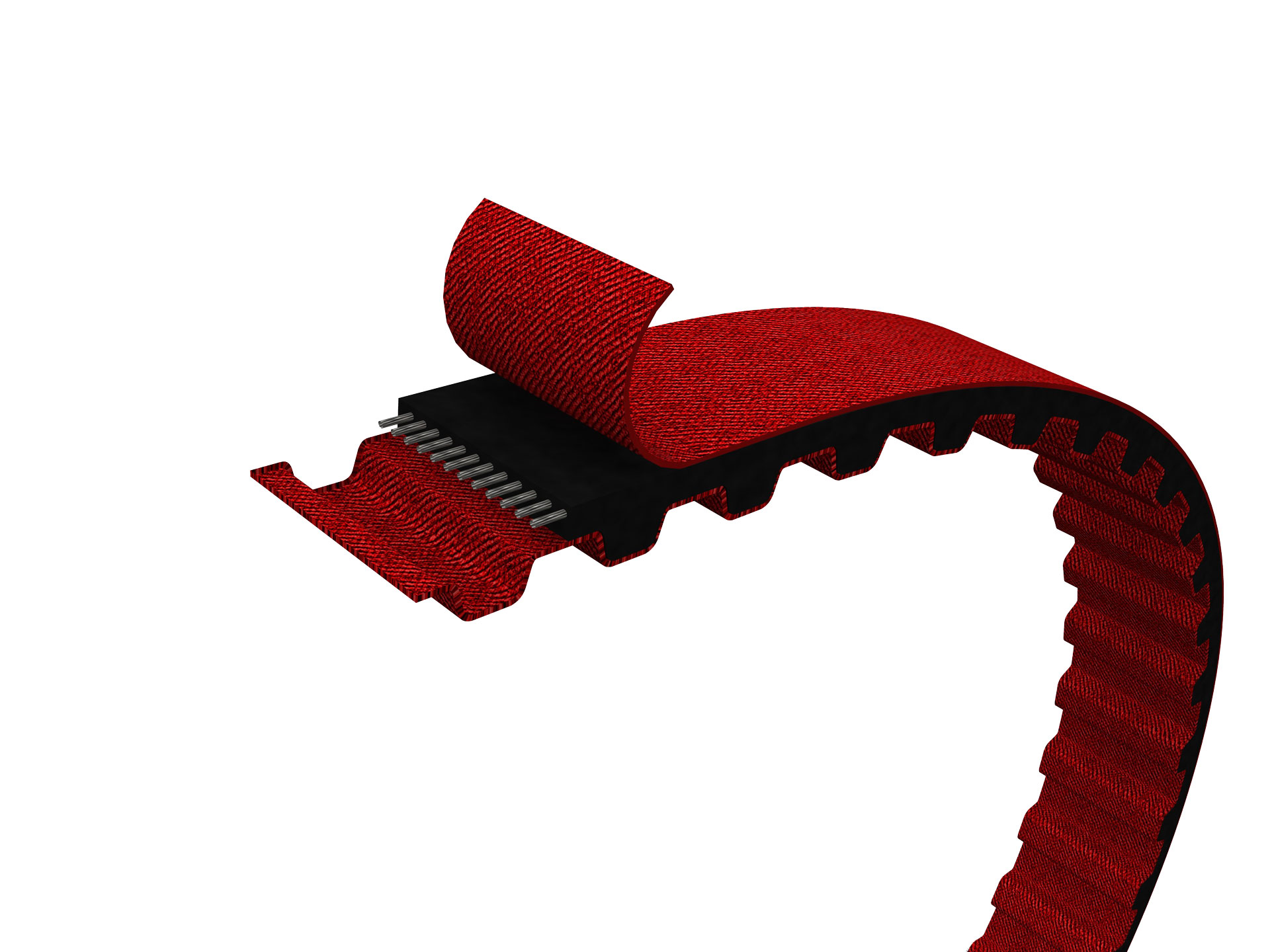

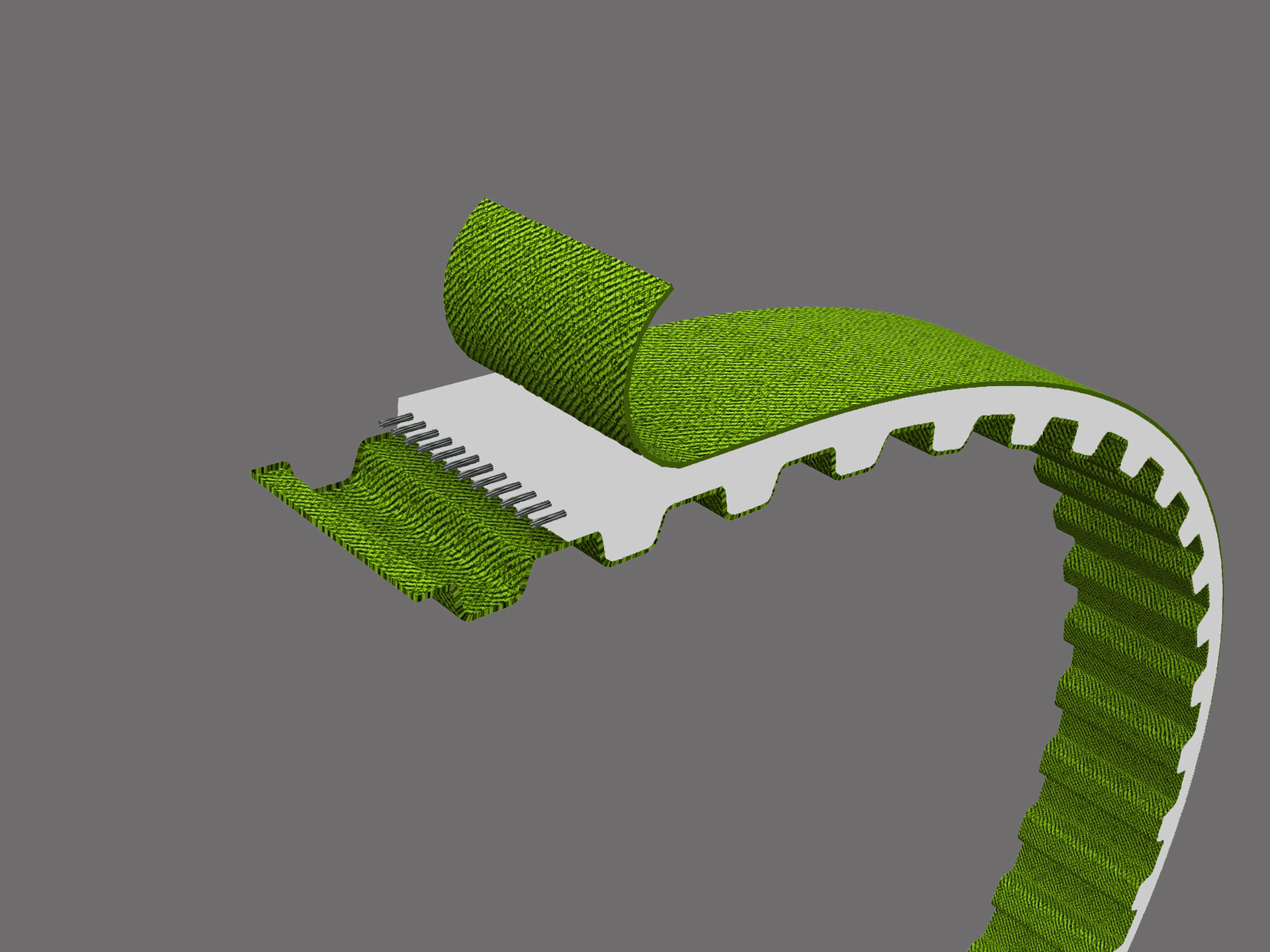

Synchrotec® Fabric optimised for your manufacturing process and the application performance process

Designed to provide benefits for the toothed and flat side of the belt:

- Reduced noise

- Reduced friction

- Resistance to pulley abrasion

- Prevents cracks forming and propagating at the surface

Benefits to the user:

- Reduced replacement costs

- Improved machine efficiency

- Close contact with development team

- Fabrics suited to individual requirements

Explore our products

Fabrics for Rubber Belts

The most complete range of fabrics for multiple applications, covering many different profiles and pitches.

Created from:

- Polyamide (nylon) 6.6

- High tenacity polyamide (nylon) 6.6

- Aramid

Available in ranges of:

- Weight (50-780gsm)

- Width (920-1500mm)

- Gauge (0.3-2.2mm)

- Stretch extensions tailored to customer belt requirements

Features and benefits of our rubber belting fabrics:

- Submersive aqueous-based adhesion promotion system for HNBR, CR, CSM, EPDM – low environmental impact

- RF-free options – for global stewardship

- Anti-static variance – for volatile environments

- Multidirectional stretch – allows for maximum toothed conformability (slit to design requirement)

- Weave patterns designed to allow for optimal belt efficiencies

Fabrics for Plastic (TPU) Belts

The most complete range of fabrics for multiple applications, covering many different profiles and pitches.

Created from:

- Polyamide (nylon) 6.6

- High tenacity polyamide (nylon) 6.6

- Polyester – Foodsafe grade (FDA and EU compliant)

Available in ranges of:

- Weight (120-440gsm)

- Width (16-1500mm)

- Gauge (0.56-1.65mm)

- Stretch extensions up to 120%

Features and benefits of our plastic belting fabrics:

- Fabrics PU dipped – for maximum abrasion and adhesion performance

- Submersive aqueous-based adhesion promotion system – low environmental impact

- Antistatic PU dip – for volatile environments

- Multidirectional stretch – allows for maximum toothed conformability (slit to design requirement)

- Weave patterns designed to allow for optimal belt efficiencies